Pulp Mill Power Boiler Chemical Cleaning

Job Scope:

A pulp mill reached out to Atlantic Flushing & Testing Inc. (AFT) to perform chemical cleaning services on their power boiler. The last cleaning of the power boiler was performed 15 years ago. Since then, regular use has increased the amount of water scale buildup in the boiler tubes which led to failure or loss of performance. Boiler tube scale is caused by suspended minerals and organic matter in water settling out on the metal surface, which leads to a hardened deposit. This interferes with heat transfer capability and may cause local overheating in the tubes. The overall decreased heat transfer capability of the boiler increases the energy costs of the mill.

The Solution:

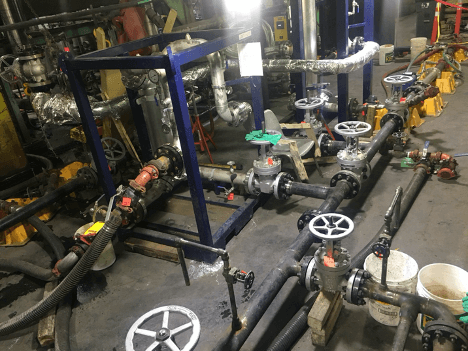

AFT mobilized a crew to site and installed the necessary pumps heat exchangers, flow meters and chemical tanks for the cleaning. The procedure involved multiple solvent stages consisting of inhibited hydrochloric acid soaks and an alkaline boil out. Chemical waste from drains and rinses from the power boiler were neutralized as required in-line by AFT and sent to waste frac tanks. On site testing was performed by our chemist during each stage which measured copper and iron concentrations, solvent strengths, conductivity and pH.

The Results:

The project was successfully completed ahead of schedule and AFT met all of the project goals. The HCL solution contained over 14000 ppm of iron scale removed from the boiler, which equates to over 3,000 lbs of material removed from the tubes. All of the waste generated from the cleaning was neutralized on site to lower the cost of waste disposal. The cleaning resulted in increased equipment efficiency, lowered operating costs and increased reliability of the boiler.