Plate Heat Exchanger Chemical Cleaning

Job Scope:

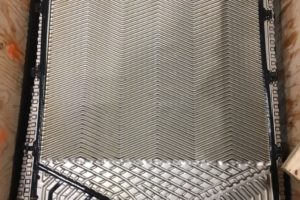

AFT was contacted by a client to perform a chemical cleaning on heat exchanger plates as part of a refit onboard a marine vessel. These plates are exposed to hot process water, as well as cold sea water. The temperature and exposure of these fluids on the plates leads to not only scale buildup, as well as growth of marine life. These conditions after some time lead to decreased heat transfer efficiency within the system, and can cause regular maintenance issues.

The Solution:

The plates were removed from the heat exchanger by the client and sent to the AFT shop in Dartmouth. A chemical cleaning procedure was drafted to specifically remove scale and marine growths simultaneously. The plates were dipped into a circulated hot chemical bath, for 6-8 hours. After the soak the bath was neutralized for proper disposal, and the plates were removed from the bath. The plates showed significant reduction of the scale and marine growths that were initially found on the plates. Plates were further washed down with water to ensure the plates were free of all scale and marine deposits.

The Results:

The plates after cleaning were found to have no marine or scale particulate left on their surfaces. These cleaned plates will lead to increased efficiency, and reliability for heat transfer operations onboard the vessel.